OxyPower HTC™

Makes wet waste valuable

Converts wet sludge into clean bio-coal

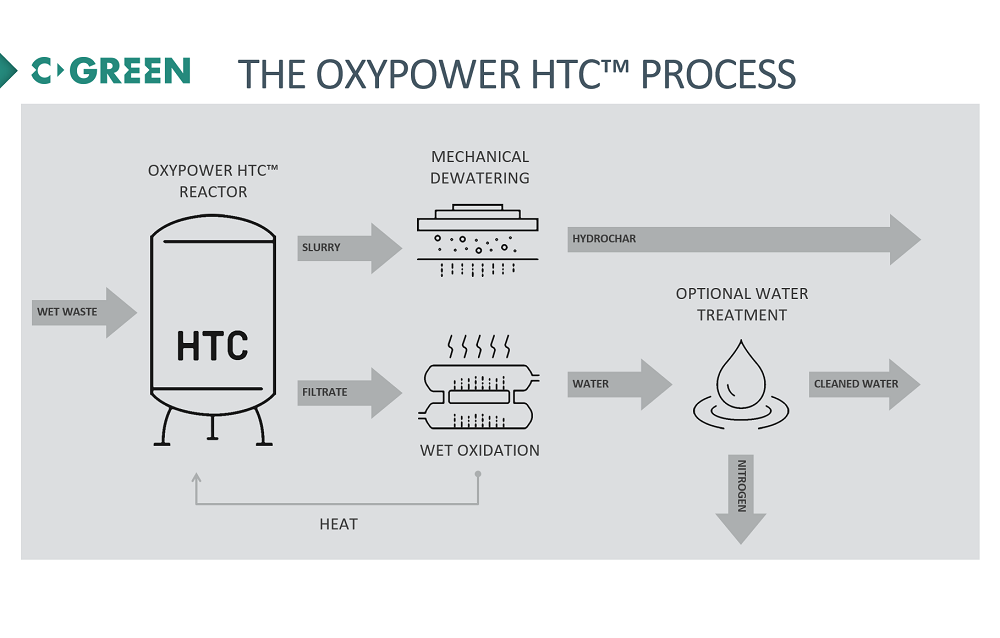

A solution based on hydrothermal carbonisation allowing separation of phosphorous and heavy metals from sludge, degeneration of toxins, deactivation of pharmaceuticals and transformation of the remaining sludge into bio-coal.

The need

Wastewater treatment plants worldwide produce sludge, which is a complex stream to handle. While sludge contains valuable nutrients, it also contains bacteria, pharmaceuticals, toxins and heavy metals. Disposal costs are high and environmental targets have not been met.

The solution

C-Green offers a compact, robust and efficient process solution to treat and provide value for wet waste. The technology is a unique and patented combination of two chemical processes: hydrothermal carbonisation and wet oxidation, which enables the easy separation of solids and water contained in the sludge. Sludge is finally transformed into hydrochar, a dried, inert, sterile, odourless material, which could provide value as a fertiliser, as a biofuel, or as a CCS solution.

The value proposition

- Turns harmful sludge into homogenous, sterile biofuel with a high energy density for power production.

- Facilitates recovery of nutrients.

- Gives municipalities or sludge owners more flexibility in how to handle sludge.

- Allows municipalities to anticipate changes in regulations.

- Offers very relevant synergies with biogas production.