Inspect Pro Control

Camera-based optimisation of multi-fuel burners enables the integration of more renewable and residual fuels in the cement industry.

Cement production with reduced CO2 emissions and fuel costs

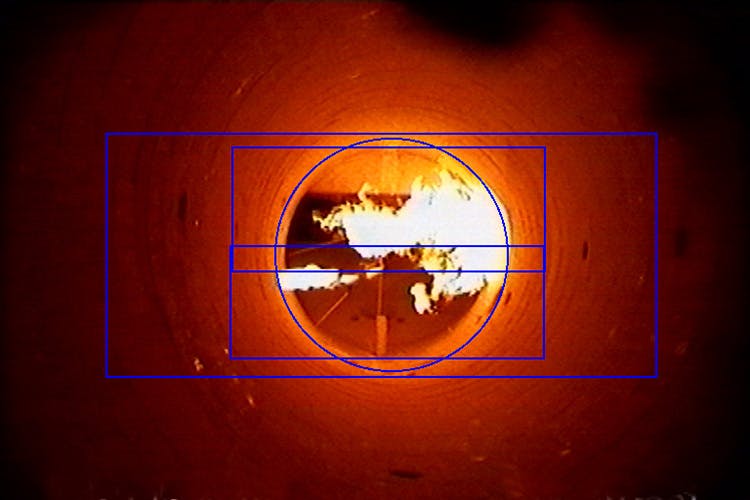

Software package for optimisation of burner control. Camera system to be coupled with software.

The need

There is a requirement to make cost savings and reduce CO2 in cement production. While the use of low-rank fuels is a solution, varying fuel compositions require an appropriate process control for the permanent adjustment of burner parameters, since it directly impacts upon product quality.

The solution

Inspect Pro Control (with the use of new camera systems in conjunction with powerful image processing systems) provides a solution with process optimisation taking place through the burner control. It maximises on the usage of alternative fuels by controlling the quality of the product (lime).

The value proposition

• 10% reduction of CO2 emissions and fuel costs; ROI in less than 1 year.

• Cement kiln operators will be able to recognise process problems earlier.

• Increased energy output, decreased emissions and stabilised combustion.

• Lower operational costs.