Cellulose micro-/nanofibers

FineCell develops and produces one of the most attractive and versatile bio-based materials of the future, micro- and nanocellulose. Our patented technology enables us to offer sustainable material solutions with unique performance benefits. Our products also offer new bio-based alternatives to replace the fossil and often harmful chemicals in personal care products and consumer goods.

Cellulose micro-/nanofibers for enhanced product performances and reduced carbon footprint

The need

Bio-based and bio-degradable high-performance materials are required to enable manufacturers to phase out harmful and fossil-based chemicals and reduce the carbon footprint of their products.

The solution

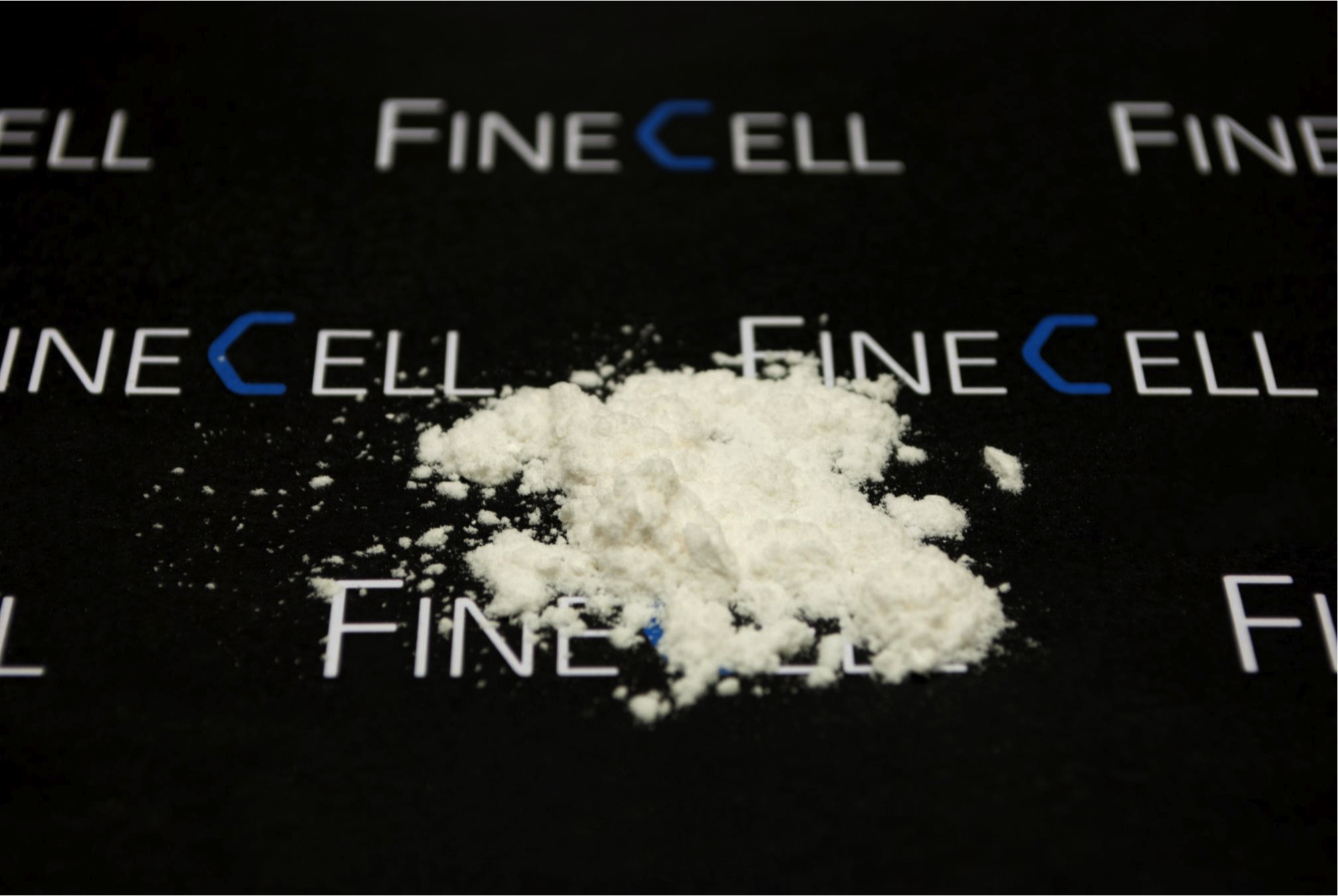

FineCell has developed sustainable cellulose micro-/nanofibers that can act as reinforcements to help manufacturers make more sustainable products using bio-based raw materials. This solution helps replace fossil and often harmful chemicals with healthy alternatives.

The value proposition

- The easily-dispersed product saves significant amounts of energy in transportation and use.

- Stabilises emulsions and dispersions.

- Tunes rheological properties of liquid and gel formulations.

- Enables easy spread and spray of thick formulations.

- For personal care: improves moisturising effects, carrier for active ingredients, excellent biocompatibility, film forming, great skin feel, neither greasy nor sticky.

- For paints & coatings: improves mechanical properties (e.g., scratch resistance).

- Other applications: thin films, gas barriers, 3D bio-printing.