ADE 6000

DRY TEXTURING volume production technology for use in the PV solar cell manufacturing industry leveraging the cost savings of diamond-wire cut multicristallyne wafers and novel wafer technologies

Dry etching at the price of wet

Universal Dry Texturing. Atmospheric Inline produtcion. Zero GWP chemistry. Water FREE processing.

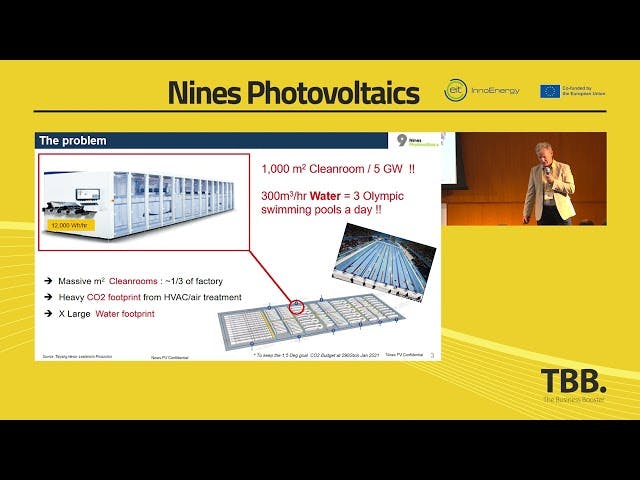

The need

Solar cell Gigafactories required for the energy transition pose an environmental challenge. Wet etching technologies require high water consumption and process inefficiently. Large numbers of very long machines are required and take up significantly more factory space.

The solution

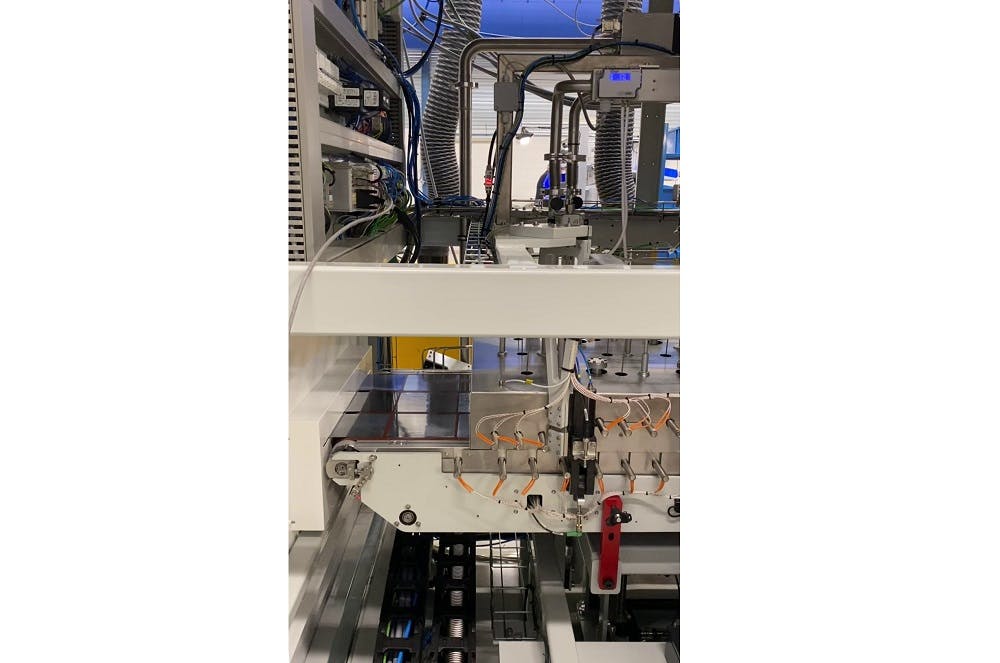

ADE is a high efficiency/low cost dry etching technology. Its very high etching rates enable Gigafactory throughputs, small machine size and reduced water impact. Unlike existing dry processes such as RIE, developed for the semi-conductor industry, the ADE process does not require costly vacuum or plasma equipment and emits no greenhouse gases. ADE is a single side process, enabling the latest solar cell architectures such as TOPCON and IBC.

The value proposition

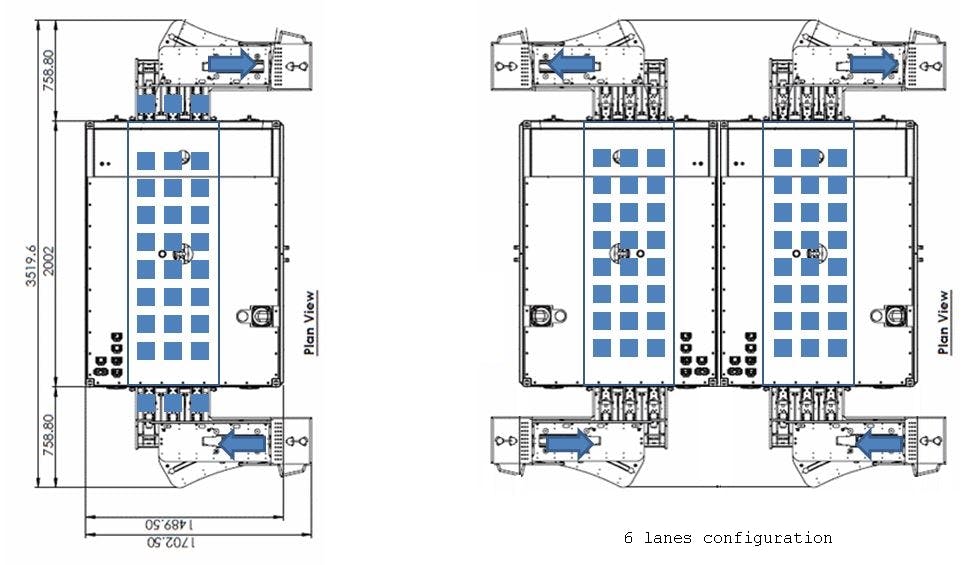

- High throughput capacity = less tools required per GW of factory capacity.

- Small tool footprint = reduced number of tools, factory size and associated costs and CO2.

- No water usage, no GHG = sustainable PV manufacturing.

- On-site gas generation = scalable manufacturing.

- Single side and selective etching = enables newest cell architectures like TOPCON and IBC.

- Patented European innovation.