Reducing CO2 emissions at the Port of Rotterdam with an innovative supercapacitor solution

Skeleton’s supercapacitors cut Maja Stuwadoor’s crane fuel use by 25%

The challenge

Maja Stuwadoors provides stevedoring services, such as storage, unloading/loading of vessels, and trans-shipment of bulk goods and general cargo for customers at the main Dutch seaports. As emissions controls become more stringent, companies operating at shipping ports need to find ways to reduce energy consumption, enhance sustainability and minimise the environmental impact of their operations.

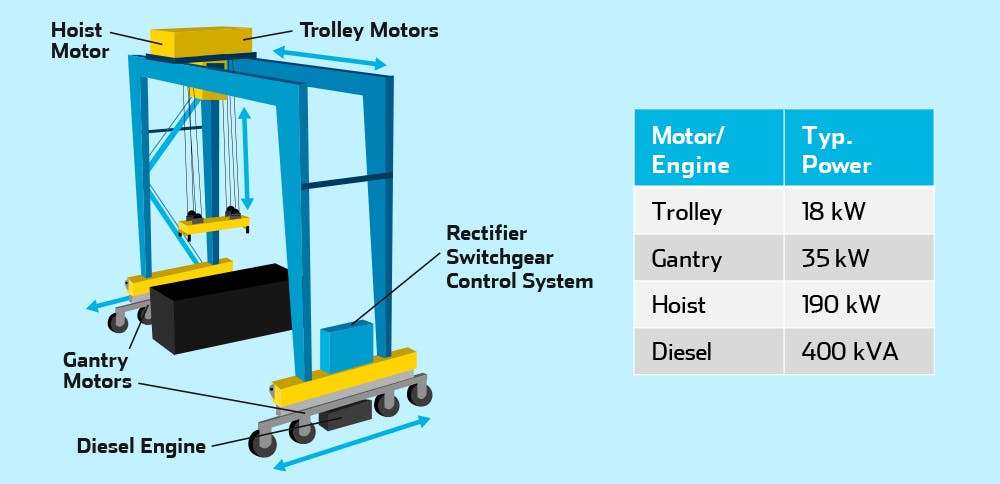

Maja Stuwadoors operates seven floating cranes and one shore crane at the Port of Rotterdam, all powered by diesel. Replacing these with fully electric solutions is not viable, so the company needs a way of adapting the cranes for greater energy efficiency. To this end, Maja has been retrofitting their port cranes with Skelton supercapacitors.

The solution

The impact

By retrofitting their cranes at the Port of Rotterdam with Skeleton’s supercapacitors, Maja has reduced its fuel use (and related emissions) by 25%, as Maja now needs one less 800 kW diesel engine to operate its cranes.

Furthermore, the company can avoid high peak loads on the grid (peak shaving) and mitigate voltage and frequency fluctuations as the regenerated energy can be reused at specific times. Noise pollution is also reduced from one less engine, and the longer lifespan of the supercapacitors compared to traditional li-ion solutions generates further cost savings.

ONE LESS DIESEL ENGINE

LESS FUEL CONSUMPTION